Mugen 3: hands-on

The cooler has six heatpipes with the classic U-shape, with a diameter of six millimeters. The total dissipating area is characterized by 48 aluminum fins split into four towers, connected in the middle by a single horizontal body. Another interesting aspect, which is peculiar to Scythe solutions, is the small passive cooler just above the base and the heat-pipes. This solution allows to obtain optimal thermal efficiency even with small TDP CPUs, so in situations of low load. This confirms what we stated above, namely that Scythe has tried to make this product as complete as possible.

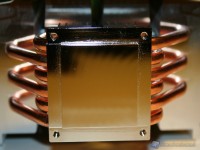

The thickness of the fins, the number and quality of heat-pipes, and the finish are good. Concerning the contact base, although there are some signs of the turning process (a factor that still does not significantly affect the performance of this unit), the surface is polished. The base is always a good indicator of the quality of the heatsink itself and here we can say that we are fully satisfied. The nickel plating does not present extraordinary finish, but at the same time turns out to be really good. Very positive, characteristic of most Scythe products, is the finish of the heat pipe which are equipped with an aluminum nickel-plated cap in order to hide the bare heat-pipes termination: this undoubtedly gives a much more professional aspect to the product.

By analyzing the arrangement of heat pipes itself through the radiant body, we see that they are not placed on the same line but in staggered blocks of 2. This will allow optimum ventilation of the heat-pipes itself, which would not have been possible if they were parallel. Surely, several studies have been carried out in the field of heat dissipation, and we believe that the MAPS system is really interesting, though perhaps not suitable for fanless configurations, because, as it is conceived, it is essential that there is a constant air flow. As evidence of this, just think about the values of the fan itself, about which we report technical specifications:

- Mugen 2: 0 – 74.25 CFM, 0 – 126 m³/h

- Mugen 3: 14.7 – 88.11 CFM, 24.95 – 149.59m³/h

Compared with the Mugen 2, in this case the fan presents a minimum of 14.7 CFM air flow.

Finally the fan fixing system is really great, easy, fast and very stable. There is nothing worse than a system that is not able to hold fans firmly to the heat-sink: this is not the case of the Mugen 3, which allows you even to adjust the height, thus avoiding the impact with onboard components such as heatsinks for the VRMs of the motherboard or RAM. The fan of course can be installed either on the front or on the rear of the heatsink.

There are no anti-vibration rubber mountings for the fan and the heatsink is not designed to improve the dissipation of the components of the motherboard or RAM, but this is a peculiarity of all the tower heat-sinks whose objective is to maximize the efficiency taking advantage of the cooler air flows inside the cabinet. Note carefully that the fan is slightly detached from the middle part of the dissipating body: this, together with the small size of the engine of the Slip Stream fan, allows a homogenous flow through the cooler, avoiding the classical vacuum in the central part due to the "shadow" of the engine.